Automation

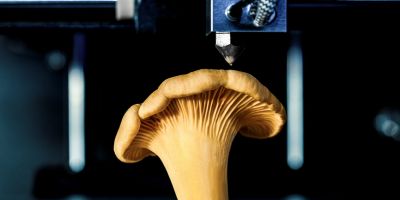

Automation relies on a maximum of customising. Highly complex parts, small batches, and varied product properties are always a challenge for engineers. Besides a machined production, we can also rely on 3D printing to build prototypes or simulate functions. Requirements such as smooth-running, weight reduction and minimising wear require more and more frequently the use of high-performance plastics.

From simple construction parts to suction cup and up to complex gripper arms for robots, we can offer an endless range of parts that we usually develop with our customers. Typical products are spacers, scrapers, clamping parts, damping elements, housing components, hinge joint, holder, all sorts of guides, ball seats, coupling parts, bearings, towing arm, profile rings, guards, expansion sleeves and valve seats.